Company Vision

Striving to become a first-class modern industrial equipment manufacturing enterprise, serving the industry and contributing to society.

Company Vantage

Chunhua Group has participated in the production of cranes for national roads, railways, construction enterprises, mining and industrial plant etc. We have a wealth of experience and have undertaken many multi-billion dollar large and medium-sized projects.

The company has more than 27 years crane manufacturing experience. 4200+ partners. 450+ Employees. factory area of 73000 square meters .

Cumulative revenue in the last three years exceeded $1 billion.

Chunghwa Group attaches great importance to quality and innovation.

Chunhua Group has passed multiple domestic and foreign certification licenses. The company has a crane research and development team of 41 highly educated people, and The product has passsed ISO9001-2000 quality system certification, And Chunhua group have participated in the formulation of 3 cases of national standards. More than 130 patents for inventions. The quality is top notch.

Choose us, we are worthy of your trust, let us win-win co-operation!

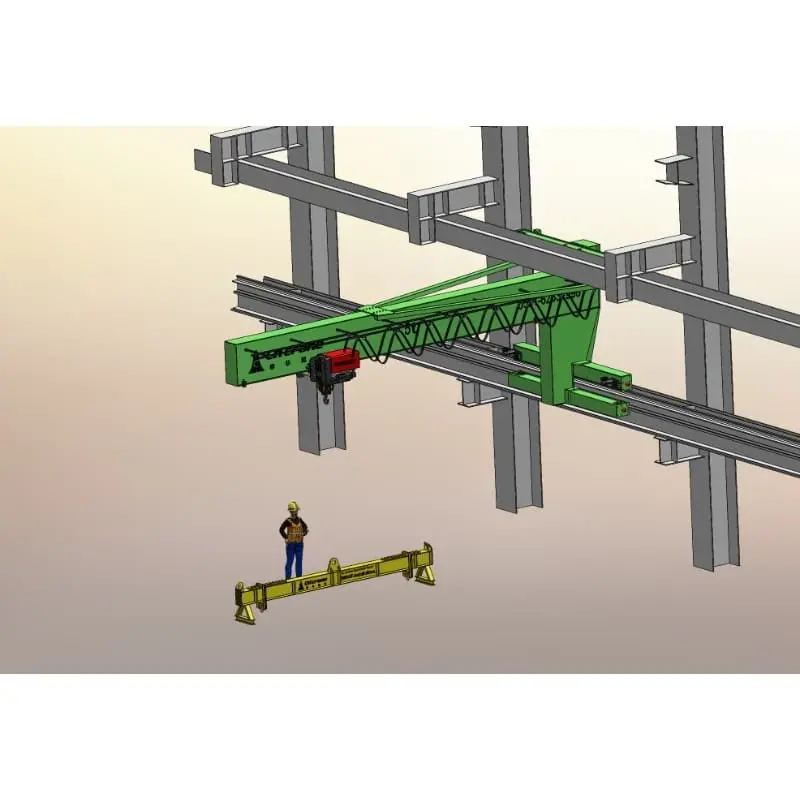

Product Introduction

High stability

System strength due to closed box section

Excellent travel characteristics

Smooth traveling under high loads thanks to the smallest tolerances for runway errors, misalignment and alignment

Low-vibration operation due to horizontal travel units and vertical travel units made of torsionally stiff, closed box section

Vertical travel unit with perfectly coordinated Demag components

Excellent driving dynamics thanks to offset geared motor (pole-changing or variable speed with frequency inverter)

Gentle and radial force-free torque transmission by coupling the drive to the wheel block

Maintenance-free wheel blocks with self-lubricating spheroidal-graphite iron travel wheels for minimal crane runway and travel wheel wear

Travelling hoist with versatile rope hoist

monorail hoist

Optimal use of space and height thanks to compact design (low approach dimensions and large hook path)

Low-swing transport due to infinitely variable lifting and travel

Service-friendly operation facilitated by comprehensive monitoring via app

Ergonomic controls

For low-fatigue, safe handling

Optional extras: DRC wireless controls with variable-frequency transmission for undisturbed transmission and reception

Optional tandem operation

For transporting particularly heavy and bulky loads

Master-slave control of both cranes with one transmitter

Synchronized safety cut-off of both cranes

System integration

Integration into overall intralogistics concepts

Modular design

Highest quality and reliability thanks to components from the modular system

Applicable Scenarios

Some of the uses and applications of our wall-mounted overhead cranes include:

- Material handling in workspaces – wall-mounted jib cranes are useful for moving heavy loads within a smaller space with precise control. Our machinery provides extensive maneuverability when handling loads ensuring improved efficiency.

- Loading and unloading of trucks – As noted above, wall-mounted jib cranes are strategically engineered to be positioned to cover a broad area making them ideal for loading and unloading of materials on and off of trucks.

- Assembly line assistance – One of the many benefits of wall-mounted cranes is their reliable means of lifting and positioning components. Not only does this make the assembly process more efficient, but it reduces injuries in the workplace.

The Service Provides

1.Pre-sales Service: We offer professional customization of Wall Travelling Crane according to customer requirements.

2.After-sales Service: Within one year, any damage caused by product quality issues will be replaced free of charge.

3.Product Inspection: The equipment inspection needs to be handled by the local relevant department. Upon delivery, we will provide all necessary documentation for the Wall Travelling Crane