Company Vision

Striving to become a first-class modern industrial equipment manufacturing enterprise, serving the industry and contributing to society.

Company Vantage

Chunhua Group has participated in the production of cranes for national roads, railways, construction enterprises, mining and industrial plant etc. We have a wealth of experience and have undertaken many multi-billion dollar large and medium-sized projects.

The company has more than 27 years crane manufacturing experience. 4200+ partners. 450+ Employees. factory area of 73000 square meters .

Cumulative revenue in the last three years exceeded $1 billion.

Chunghwa Group attaches great importance to quality and innovation.

Chunhua Group has passed multiple domestic and foreign certification licenses. The company has a crane research and development team of 41 highly educated people, and The product has passsed ISO9001-2000 quality system certification, And Chunhua group have participated in the formulation of 3 cases of national standards. More than 130 patents for inventions. The quality is top notch.

Choose us, we are worthy of your trust, let us win-win co-operation!

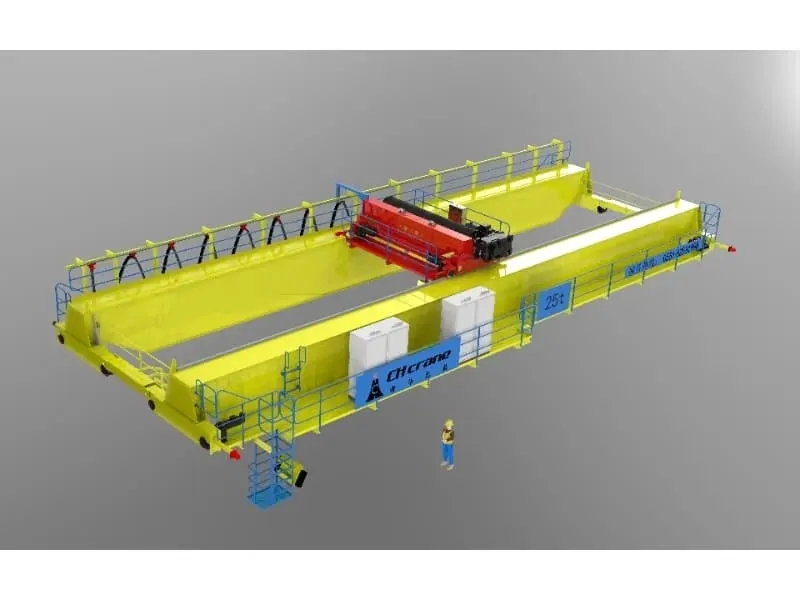

Product Introduction

This Crane including high end-product and ordinary product.

High end-product gearbox use SEW, FLENDER, stepleess motor use SIMENS, ABB, SEW, brake use SIBRE, HUAWU.

Ordinary product use Leading advanced gearbox, stepleess motor and brake made in China.

Feature Description

Optimazed designing, Space saving, Smaller wheel load.

Safe working load 5-500T

Aux lifting use hoist or winch

Flexible solution for all lifting needs

Excellent driving properties, stepleess speed control, smoothly moving

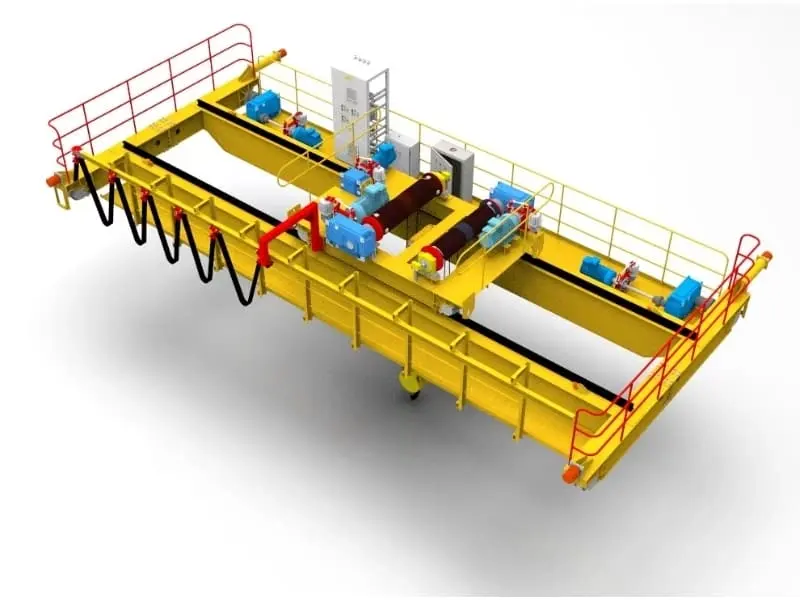

Mechanical Feature

Double welding box girder, DIN/FEM&GB

Material Fe37 or Fe52(be equal to Q235b or 355B)

Whole length CNC cutting for complete webplate, high deflecting accuracy.

Trolley rail is high strength flat steel bar(hot rolled,Q355B)

High quality auomatic welding and NDT inspecting

Short-blasting Sa2.5 for complete girder after welding, stress release

Epoxy zinc rich high quality paiting ,50*50*40with 120, shine and longevity life

High tension bolts between girder and end carriages, high accuracy and safety

Compacted gearmotor diving, stepless speed control, high gearbox, safety disck brake

High protection class IP55,F class(or H)40%ED

Double flanged or flat wheel, anti-fiction bearing, cellular buffers and derailment protectors

Service platform along the girder

Centralized lubrication system

Trolley Feature

Load 5-500T, lift height 6-113m

Modularity designing, novel structure, smaller weight, smaller shape, easily installed and serviced, need smaller building space and structural strength, so to reduce invest

Use crane dedicated frequency conversion control system, for accuracy control, reduce operational risk

Hoist use two limit switches, is safe for lifting moving

Travelling use cross limit switches

Rope drum is welded with Fe52(Q355B)and NDT inspecting

New-Style rope guide use special designed, prevent rope

Hook design use DIN15402, smaller and artistic

Safety Protection

Gearmotor locker rope t protect drop

Rain Cover for outside hoist, driving units, electric cubicle

Warning indicator: flashing lights and warning sound

Wireless infra-detector for anti-collusion

Optional Accesseies

Overspeed safety brake, Electric hydraulic block brake, safe working monitoring unit, Steel mill lifting tool, including glab, tong, magnet,etc. Glab, Electric magnet disc.

Applicable Scenarios

- 1.Manufacturing Industry: Used for loading and unloading, handling parts, or finished products on factory production lines.

- 2.Logistics and Warehousing: Used for loading and unloading, stacking, and transporting goods in warehouses.

- 3.Construction Sites: Used for lifting and handling operations on construction sites.

- 4.Port Terminals: Used for loading and unloading cargo and stacking at port terminals.

In summary, the double girder overhead crane is a powerful and reliable lifting equipment suitable for various lifting occasions and is an indispensable tool in many industries.

The Services Provide

1.Pre-sales Service: We offer professional customization of Double girder overhead crane according to customer requirements.

2.After-sales Service: Within one year, any damage caused by product quality issues will be replaced free of charge.

3.Product Inspection: The equipment inspection needs to be handled by the local relevant department. Upon delivery, we will provide all necessary documentation for the double girder overhead crane.