Chunhua Hoisting Machinery Co., Ltd. a prominent enterprise in bridge and gantry crane manufacturing, boasts a strong track record of innovation, international presence, and advanced production facilities. Our commitment to quality and expertise has made us a leader in the industry. Join us for top-notch lifting solutions and intelligent parking equipment!

What is a Double Girder Crane?

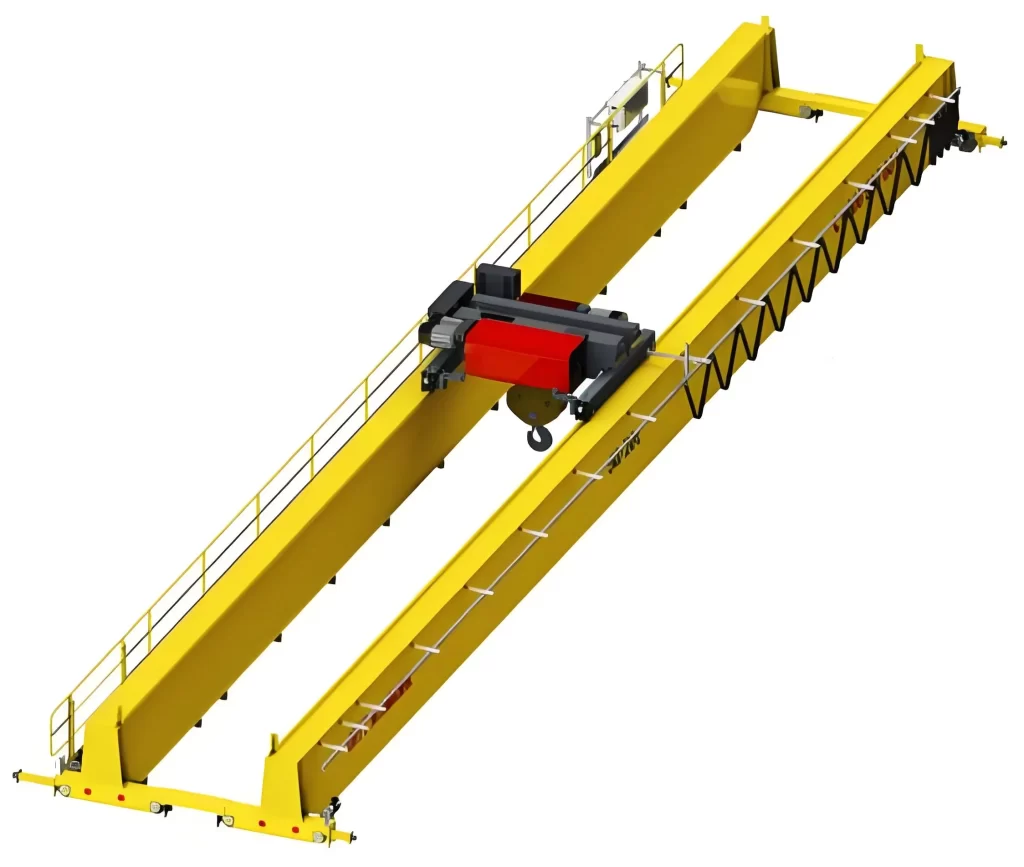

A double girder crane, also known as a double-beam crane, is a heavy-duty overhead lifting device designed to handle exceptionally heavy loads. Its robust construction features two parallel bridge girders supported by end trucks, providing exceptional stability and load-bearing capacity.

Design and Components

The bridge girders, typically made of steel for maximum strength, span the length of the crane and serve as the primary support structure. End trucks, equipped with wheels or bogies, travel along the runway beam to move the crane laterally. Hoists, suspended from the bridge girders, perform the vertical lifting and lowering operations.

Advantages of Double Girder Cranes

Double girder cranes offer a multitude of advantages that make them a preferred choice for demanding industrial applications:

Exceptional Load Capacity

The dual-girder design enables double girder cranes to handle loads significantly heavier than single-girder counterparts. The sturdy construction ensures stability and precision handling, making them ideal for tasks requiring the movement of large machinery, heavy materials, or finished products.

Increased Rigidity and Stiffness

The two parallel girders provide enhanced rigidity and stiffness, minimizing deflection under load. This ensures precise lifting and positioning, crucial for operations dealing with delicate or fragile objects. The increased rigidity also contributes to the crane's overall stability, reducing the risk of swaying or vibration.

Durability and Longevity

Double girder cranes are built to withstand heavy-duty usage in harsh industrial environments. The robust construction and high-quality components contribute to their exceptional durability and longevity, minimizing maintenance downtime and maximizing operational uptime.

Applications of Double Girder Cranes

The versatility of double girder cranes extends across a wide range of industrial settings:

Manufacturing

In manufacturing facilities, double girder cranes facilitate the movement of raw materials, semi-finished products, and finished goods. Their precision handling capabilities ensure efficient and safe transportation of heavy components.

Construction

Double girder cranes play a pivotal role in construction projects, particularly in the erection of steel structures and the placement of heavy machinery. Their ability to handle large loads at varying heights makes them indispensable for high-rise buildings and infrastructure development.

Shipyards

Shipyards rely heavily on double girder cranes to lift and position heavy components during vessel construction and repair. The cranes enable the precise and efficient movement of massive steel plates, engines, and other equipment.

Expert Advice and Tips

Harnessing the full potential of double girder cranes requires careful planning and operation:

Crane Selection

Selecting the appropriate double girder crane for a specific application is crucial. Factors to consider include load capacity, lifting height, span length, and operating environment. Consulting with experienced crane manufacturers and engineers ensures the right crane is chosen for the job.

Regular Maintenance

Proper maintenance is essential for ensuring safety and optimizing performance. Regular inspections, lubrication, and component replacements extend the crane's lifespan and minimize downtime.

Operator Training

Well-trained operators are essential for safe and efficient crane operation. Thorough training in crane controls, load handling techniques, and safety protocols empowers operators to use the crane to its full potential.

Case Study: Overcoming a Load-Handling Challenge

In a manufacturing plant, a double girder crane was tasked with handling exceptionally heavy steel beams. However, the existing crane was struggling to lift the loads due to its limited capacity. To address this challenge, the plant replaced the old crane with a new double girder crane with a higher load capacity. This investment significantly improved productivity, enabling the plant to meet its production targets efficiently.

Conclusion

Double girder cranes are indispensable tools in various industrial sectors, providing exceptional load-handling capabilities, durability, and versatility. By understanding the advantages, applications, and expert advice presented in this guide, businesses can optimize their operations and leverage the full potential of these powerful machines. Moreover, regular maintenance, proper operator training, and adherence to safety protocols ensure these cranes deliver reliable and efficient performance, enhancing productivity and workplace safety.