-

12

2024/07

Why did we hobbed gears processed by gear hobbing machines on cranes?

Reliability: Gear hobbed gears provide high precision and stable transmission, enhancing the operational reliability of the crane. Durability: High-quality gears reduce wear and extend the crane's service life. Efficiency: Optimized transmission systems improve the crane's operational efficiency and energy utilization. Safety: Precise gear transmission helps enhance the crane's safety performance, reducing the risk of accidents. Adaptability: Hobbed gears can be customized according to crane design requ...

-

11

2024/07

How to install an overhead crane?

Confirm the installation site and infrastructureInstall tracks and supporting structuresAssemble the bridge and trolleyInstall the electrical system and controllersConduct debugging and testing to ensure normal crane operation

-

09

2024/07

What is a Semi-Gantry Crane?

A semi-gantry crane is a type of bridge crane where one end beam runs on an elevated track while the other end beam runs on a ground track. It is typically used for material handling both indoors and outdoors.

-

03

2024/07

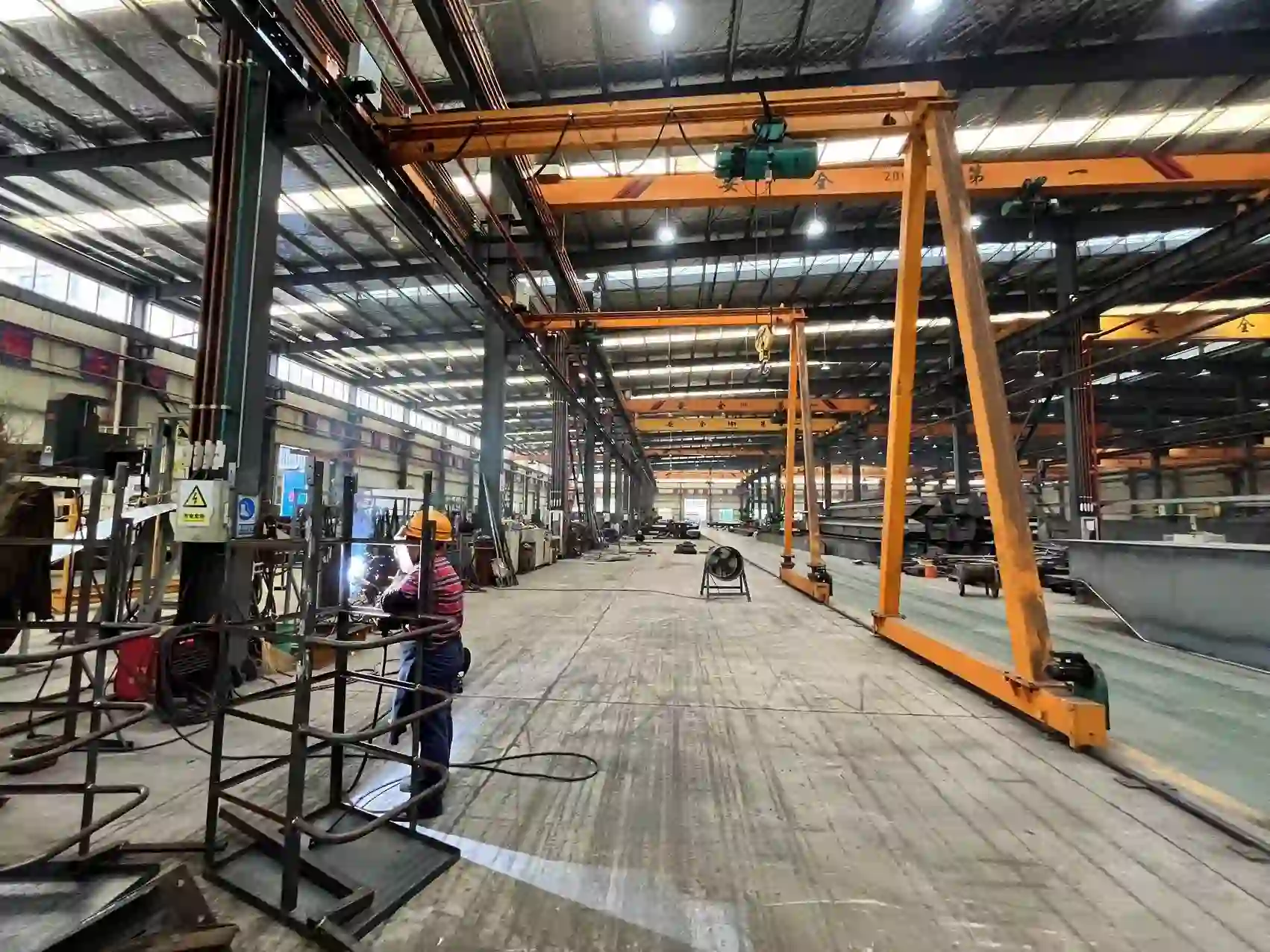

How is the steel required for crane production processed?

Material Selection and Procurement: Select suitable steel for crane applications, such as high-strength low-alloy steel (HSLA), carbon steel, or alloy steel. Cutting: Use cutting machines (such as plasma cutters, laser cutters, or flame cutters) to cut the steel plate into the desired size and shape. Forming: Shape the steel plate into specific forms, such as beams or support structures, through bending, rolling, or stamping processes. Welding: Use various welding techniques (such as gas-shielded welding, subm...

-

02

2024/07

What are the steps for producing the main beam of the crane?

Material Preparation: Select appropriate steel, usually high-strength low-alloy steel, and cut and prepare it according to design requirements. Welding Assembly: Weld the steel plates and steel beams into the basic framework of the main beam. This process requires ensuring the quality of the welds to guarantee the strength and stability of the main beam. Correction and Straightening: After welding, the main beam may deform, so correction and straightening are needed to ensure the straightness and geometric dimensions...

-

01

2024/07

Does installing a gantry crane require a foundation?

Whether a foundation is required depends on the specific model of the gantry crane and the operating environment. Here are some common scenarios: Lightweight portable gantry cranes: Usually do not require a foundation and can be used directly on a flat, solid surface. Medium and heavy-duty gantry cranes: Typically require a foundation to ensure stability and safety. The foundation prevents the gantry crane from tilting or moving during operation. Indoor gantry cranes: If the floor is sufficiently strong and level, an add...

-

28

2024/06

What are the differences between flexible KBK and rigid KBK?

Flexible KBK Crane Design: Suspended structure with tracks hung from fittings. Made of aluminum alloy or lightweight steel. Applications: Suitable for limited spaces needing flexible layouts, like assembly lines and workshops. Features: Easy to install and move, highly flexible. Smooth operation with low noise. Rigid KBK Crane Design: Fixed structure with tracks mounted on the ground or walls. Made of high-strength steel. Applications: Suitable for high load ca...

-

27

2024/06

What are the steps for Installing a Gantry Crane?

Preparation Work: Site Preparation: Clear the installation site, ensuring the ground is level and has sufficient load-bearing capacity. Equipment Inspection: Check all parts of the gantry crane for any damage to ensure they are in good condition. Personnel Training: Ensure that the installation personnel possess relevant skills and safety knowledge. Foundation Construction: Foundation Measurement: Measure and mark the foundation location according to the design drawings. Foundation Pouring: Pour th...

-

26

2024/06

What are the key components of a gantry crane?

Bridge: The main horizontal beam of the crane. Hoist and Trolley: The hoist lifts the load, while the trolley allows it to move horizontally along the bridge. Legs: The vertical supports that carry the bridge, trolley, and hoist. End Trucks: These are located at the ends of the bridge and travel along the crane's runway. Runway: The path along which the crane moves, either a track or a rail system.

-

25

2024/06

What treatments are necessary after rust removal?

After rust removal, it is necessary to clean the metal surface to ensure no rust or rust remover residues remain. Then, apply anti-rust treatments, such as rust-inhibiting primers and topcoats, or other protective coatings.

-

24

2024/06

How are gantry crane legs anchored?

The legs of a gantry crane are anchored using either fixed or mobile bases. Fixed bases are typically bolted to the ground or a foundation, while mobile bases may have wheels or tracks to allow the crane to move.

-

23

2024/06

What are the characteristics of metallurgical overhead cranes?

High-Temperature Operation: Metallurgical overhead cranes can operate in high-temperature environments, typically handling molten metals and high-temperature materials. Key components such as hoisting mechanisms and electrical systems are made of heat-resistant materials and designed with special insulation to ensure safety and reliability. Corrosion Resistance: The metallurgical industry often involves corrosive gases and liquids, requiring high corrosion resistance for equipment. Metallurgical overhead cranes are usually cons...