-

07

2025/05

How do you operate a gantry crane safely?

Safe operation of heavy gantry cranes is essential to avoid accidents and protect personnel safety. By complying with the following operating procedures and safety measures, you can effectively reduce the safety risks in gantry crane operation and ensure the safety of operators and equipment. Basic requirements and operating procedures: Preparation before operation Check the equipment: Make sure the gantry crane structure, electrical system, hydraulic/pneumatic system, chains, wire ropes, brake system, signal equi...

-

17

2025/04

What is the Difference Between a Jib Crane and A gantry Crane?

Jib cranes and gantry cranes are two common lifting equipment. They have many differences in structure, working principle, application scenarios, etc. Jib crane vs gantry crane Structural composition Jib crane: It is composed of columns, cantilever beams, hoisting trolleys and slewing mechanisms. The columns are fixed, the cantilever beams can rotate, and the hoisting trolleys run along the cantilever beams. Adjustable Gantry Crane: It is composed of a bridge, a trolley running mechanism, a trolley running ...

-

02

2025/04

What is the relationship between electric chain hoists and cranes?

Electric chain hoist is a kind of lifting equipment driven by electricity, used to lift various heavy objects. Its working principle is to drive the movement of the ring chain through the motor, and lift the object through the lifting effect of the chain. Electric chain hoist lifting equipment is generally composed of motor, reducer, ring chain, hook and control device. Main features: High efficiency and energy saving: It is driven by electricity, has high efficiency and can work stably for a long time. Strong loa...

-

20

2025/03

Several common types of suspension cranes

There are many types of suspension cranes, each with different designs and uses to suit different working environments and needs. Common types of suspension cranes: Suspended bridge crane Features: Suspended bridge cranes are usually supported by two rails, with the boom suspended on the bridge and can move laterally between two supporting points. Application: Widely used in workshop production lines, warehouses, steel mills, shipyards and other places. Single girder suspension crane Features: The cra...

-

05

2025/03

What are the product advantages of suspension crane equipment?

Suspension crane is a commonly used lifting equipment, which is widely used in various industrial and construction fields. Product Advantages Save space Suspension design: The boom of the suspension crane is suspended in the air, which does not need to occupy ground space, effectively utilizing the limited working area, and is particularly suitable for use in small spaces. Wide coverage area: The highly flexible suspension crane allows the crane to cover a larger working range and has strong adaptability. ...

-

25

2025/02

Suspension crane load capacity and stability

The load capacity and stability of a suspension crane are two important factors in its design and use, which directly affect the safety and efficiency of operation. Load capacity: Design load capacity: The load capacity of a flexible suspension crane is usually determined by its structure and the materials used. Its design load capacity can range from a few tons to tens of tons, depending on the model of the crane, the manufacturer and the requirements of the working environment. Influence of working condition...

-

11

2025/02

Jib Crane VS Suspension Crane

The comparison between jib crane and suspension crane is mainly reflected in the following aspects: Structural design: Jib crane: It has a fixed support arm, one end of the arm is fixed by a support column, and the other end is used to lift the load. It is usually used for operations in smaller spaces such as factory workshops and warehouses. Suspension crane: The load part of the single-beam suspension crane is suspended in the air by hanging and moved by tracks or rails. It is usually used in large construction...

-

17

2025/01

Application areas of automated cranes

Application areas: Port and shipping industry In large ports, automated cranes can achieve unmanned operation through intelligent control systems, automatically completing tasks such as stacking, moving, loading and unloading of containers. Improve operating efficiency and reduce safety risks caused by manual operation. Intelligent automated crane are equipped with Internet of Things technology to monitor equipment status in real time, perform fault diagnosis and early warning, and improve port operation efficienc...

-

06

2025/01

Gantry Crane: An Efficient Solution for Industrial Material

A gantry crane is a type of crane that is used in various industrial environments for lifting and moving heavy materials. It operates by traveling along a track and is typically used in industries such as shipping, construction, manufacturing, and logistics. Below are some key reasons why gantry cranes are considered an efficient solution for industrial material handling: 1. Versatility and AdaptabilityDifferent Types of Loads: Gantry cranes can handle a variety of loads, from heavy construction materials to shipping contai...

-

27

2024/12

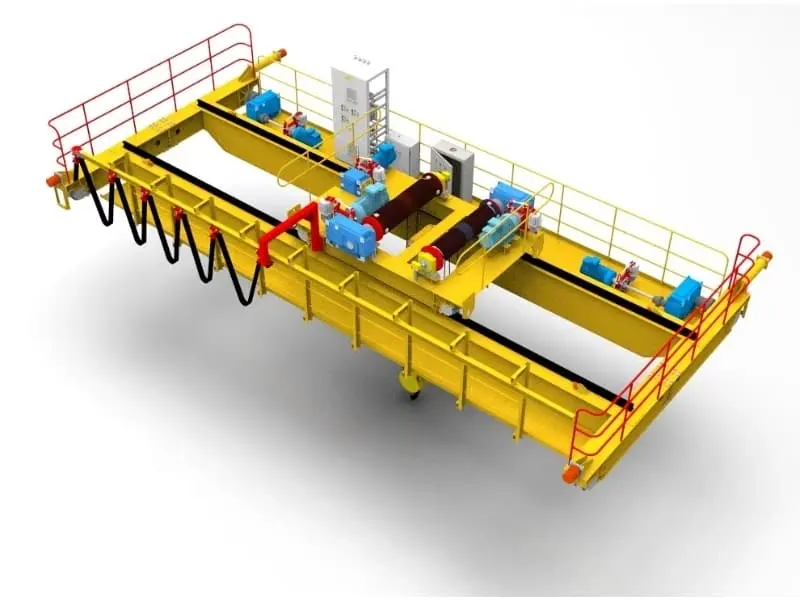

What is the use of double girder crane?

A double girder crane is an overhead crane designed with two parallel girders (beams) that support the bridge and the lifting mechanism. This configuration makes double girder cranes suitable for handling heavy loads and applications requiring increased lifting height, stability, and precision. Below are the primary uses and benefits of double girder cranes: 1. Handling Heavy Loads:Double girder overhead cranes are ideal for applications that involve lifting and transporting very heavy loads, such as large machinery, heavy ...

-

05

2024/12

Applications and uses of cantilever cranes

cantilever cranes (also known as arm cranes, Jib cranes) have adjustable arm lengths, are flexible to operate, and take up little space. Through the combination of brackets and rotating arms, they can carry and lift heavy objects within a certain range and are widely used in various industries. Main applications and uses of cantilever cranes: 1. Workshops and Factories Use: cantilever cranes are widely used in manufacturing workshops to transport, assemble and position heavy equipment, parts or tools. Advantage...

-

19

2024/11

Double Girder Crane VS Single Girder Crane

When it comes to bridge overhead cranes, single girder and double girder cranes are two of the most common types. Each has its own set of advantages and limitations, making them suitable for different applications depending on factors like load capacity, height requirements, and space considerations. Below is a detailed comparison of both types of cranes: Choose a Single Girder Crane if your operation involves lighter loads, requires less headroom, or is operating in a space with height constraints. It’s also the mo...