Chunhua Group developed based on years of experience in serving mines, the relining crane is suitable for enter or exit.

Company Vision

Striving to become a first-class modern industrial equipment manufacturing enterprise, serving the industry and contributing to society.

Company Vantage

Chunhua Group has participated in the production of cranes for national roads, railways, construction enterprises, mining and industrial plant etc. We have a wealth of experience and have undertaken many multi-billion dollar large and medium-sized projects.

The company has more than 27 years crane manufacturing experience. 4200+ partners. 450+ Employees. factory area of 73000 square meters .

Cumulative revenue in the last three years exceeded $1 billion.

Chunghwa Group attaches great importance to quality and innovation.

Chunhua Group has passed multiple domestic and foreign certification licenses. The company has a crane research and development team of 41 highly educated people, and The product has passsed ISO9001-2000 quality system certification, And Chunhua group have participated in the formulation of 3 cases of national standards. More than 130 patents for inventions. The quality is top notch.

Choose us, we are worthy of your trust, let us win-win co-operation!

Product Introduction

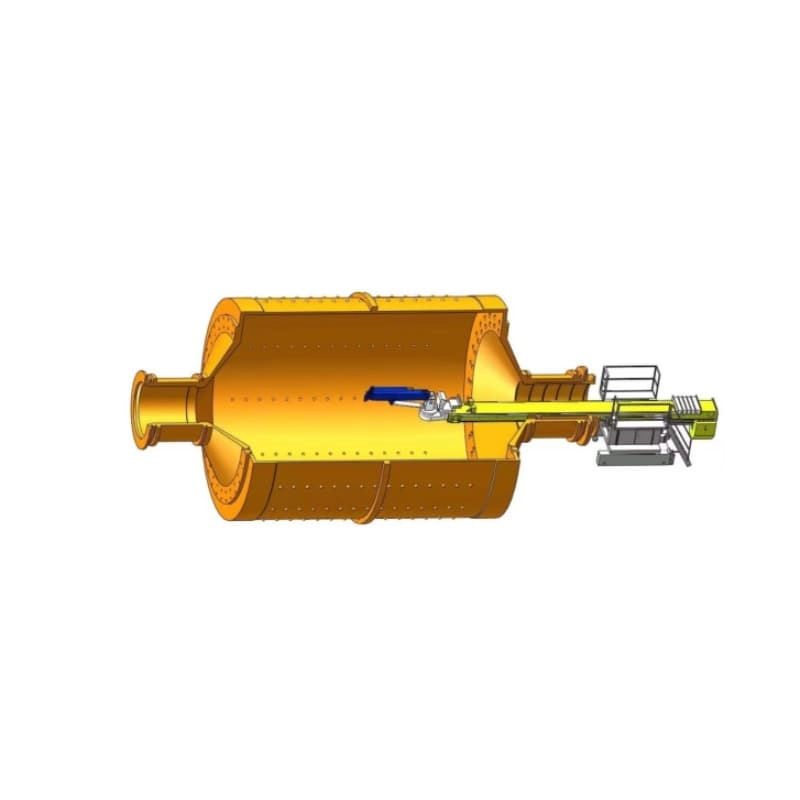

1: Various ball mills, semi-autogenous mills or ball mills with machine calibre opening larger than 1.1 metres. Semi-autogenous mill liner replacement indispensable good helper. Chunhua brand JXS type relining crane from the beginning of research and development to the present large-scale input to industrial and mining enterprises After five years, the product specifications have been improved from I-type to V-type, more in line with the actual use of the production site, is the autogenous semi-autogenous mill relining crane indispensable good helper.

2: JXS relining crane to the most advanced lining replacement technology as the goal, and combined with the broad market prospects in the country, the development of the product economy, durability, is a substitute for foreign imports of products.

3: The product design is analysed by finite element software, which has greatly improved the service life and working frequency of the product.

Features of relining crane

1: Clever design, easy to maintain

2: Hydraulic system standardisation, applying universal components, hydraulic parts, supporting parts inventory to keep a minimum.

3: Extremely low failure rate

4: You can choose track type, wheeled ground walking.

5: Specifically designed for each mill, maximum efficiency and minimum cost.

The product systems are broadly divided into the following categories:

1: Hydraulic system

2: Crane system

3: Trolley drive system

4: Electrical system

5:Frame system

6:Lining trolley

7:Main beam travelling mechanism

Brief description of the relining crane system

1: There are two kinds of relining crane driving system

1)Rail-operated drive

The standard configuration is rail running type, customised according to the gauge of the track laid on site, this form runs smoothly and noiselessly. This form runs smoothly and noiselessly. The mechanism can be aimed with the track when the crane is working.

2)Rail-less drive

However, it can also be run without rail according to customer's requirement.

The running mechanism adopts steel wheels covered with high-strength polyurethane, which can walk autonomously on the paved road under the drive of hydraulic motors. Adopting four hydraulic motors to drive the wheels, it can realise in-situ steering and walking in any direction, with strong driving force of hydraulic motors, no noise and free of maintenance.

2: Main beam travelling mechanism

In order to solve the liner changing work in small space, the main beam travelling mechanism is specially developed, and the self-travelling mechanism of the main beam can be more effective and reach into the chamber of the grinding machine for more effective work. The speed reducer of the travelling mechanism is SEW brand, which is noiseless and maintenance-free.

3: Lining trolley

It is an important tool in the liner changing work, with low height, large load capacity, and can be attached to the face of the main beam to run.

It can freely move in and out of the machine calibre with diameter greater than or equal to 1.2, and the traction reducer is SEW brand.

4: Electrical system

The electrical control adopts Siemens and Schneider brand.

5:Crane system

Crane features: Hydraulic telescopic bar is external, easy to maintain. Slewing mechanism is one-piece type. No leakage, maintenance free.

Strong overload capacity, compact design and flexible movement. Can meet all kinds of narrow space for operation. The crane is equipped with lighting tools.

6: Hydraulic system

Hydraulic system is the mechanical driving source and actuator, adopting motor-driven hydraulic pump as the prime mover. The hydraulic pump adopts bolted quantitative pump. It provides power for the following mechanisms: 360°turning of boom, boom lifting and luffing, boom telescoping, heavy lifting, and so on. The system consists of the host hydraulic pipeline control part, in order to ensure the reliable operation of the machine. The operation of the crane's various working bodies are hydraulic reversing valve handling control, the hydraulic system is required to have a high degree of reliability, impact resistance and slow down the impact, and to ensure that the reliable positioning of the working bodies, hydraulic braking performance is good.